Trending...

- CredHub and Real Property Management Join Forces to Empower Franchise Owners with Rental Payment Credit Reporting Solutions

- Nextvisit Co-Founder Ryan Yannelli Identifies Six Critical Factors for Behavioral Health Providers Evaluating AI Scribes in 2026

- Price Improvement on Luxurious Lāna'i Townhome with Stunning Ocean Views

XI'AN, China - WisconsinEagle -- In material durability testing, UV Weathering Test Chambers and Xenon Arc Test Chambers are two of the most widely used instruments for simulating sunlight and outdoor exposure. Choosing between them depends on your product's material composition, testing standards, and real-world application needs.

How UV and Xenon Arc Chambers Recreate Real Outdoor Conditions

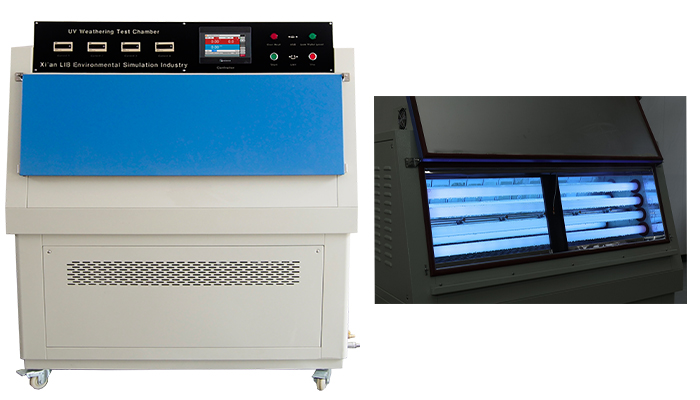

UV Weathering Test Chambers

UV Weathering Test Chambers use fluorescent UV lamps (commonly UVA-340 or UVB-313) to reproduce the short-wave ultraviolet spectrum of natural sunlight. They focus on accelerated testing of surface degradation, such as color fading, gloss loss, or cracking.

Typical Standards: ASTM G154, ISO 4892-3

Common Conditions: 35 ~ 80 ℃ black panel temperature,≥95% RH relative humidity, alternating UV and condensation cycles

Ideal For: Coatings, plastics, paints, rubber, and polymer materials

Xenon Arc Chambers

In contrast, Xenon Arc Chambers use a xenon arc lamp that closely simulates the full solar spectrum, including UV, visible, and infrared light. This makes them ideal for evaluating both color and mechanical performance over long-term exposure.

More on Wisconsin Eagle

Typical Standards: ASTM G155, ISO 4892-2, SAE J2527

Common Parameters: Irradiance 0.35–1.10 W/m² (at 340 nm), temperature Ambient ~ 100 ℃ ±2℃, humidity 50% ~ 98% RH

Ideal For: Automotive components, textiles, packaging, and outdoor construction materials

Technical Comparison: Choosing the Best Chamber for Your Material Durability Tests

If your product mainly suffers UV-induced surface damage, the UV chamber offers an efficient and economical option. However, for comprehensive sunlight simulation and color stability assessment, a xenon arc test chamber provides more realistic results.

More on Wisconsin Eagle

LIB Industry – Global Expertise in UV and Xenon Weathering Test Chambers

LIB Industry is a global manufacturer with over 16 years of expertise in environmental test chambers. We provide standard and customized solutions for UV, xenon, temperature & humidity, thermal shock, and IP dust and water ingress testing.

Supported by 5 service centers worldwide and lifetime technical assistance, LIB industry provides fast response, reliable quality, and complete testing solutions.

Website: www.libtest.com

Email: inquiry@libtestchamber.com

WhatsApp / Phone: +86 187 0087 5368

For expert guidance and tailored testing systems, contact LIB Industry — your trusted partner for environmental simulation and accelerated aging solutions.

How UV and Xenon Arc Chambers Recreate Real Outdoor Conditions

UV Weathering Test Chambers

UV Weathering Test Chambers use fluorescent UV lamps (commonly UVA-340 or UVB-313) to reproduce the short-wave ultraviolet spectrum of natural sunlight. They focus on accelerated testing of surface degradation, such as color fading, gloss loss, or cracking.

Typical Standards: ASTM G154, ISO 4892-3

Common Conditions: 35 ~ 80 ℃ black panel temperature,≥95% RH relative humidity, alternating UV and condensation cycles

Ideal For: Coatings, plastics, paints, rubber, and polymer materials

Xenon Arc Chambers

In contrast, Xenon Arc Chambers use a xenon arc lamp that closely simulates the full solar spectrum, including UV, visible, and infrared light. This makes them ideal for evaluating both color and mechanical performance over long-term exposure.

More on Wisconsin Eagle

- HBZBZL Unveils "Intelligent Ecosystem" Strategy: Integrating AI Analytics with Web3 Incubation

- Kaltra Launches Next-Gen MCHEdesign With Full Integration Into MCHEselect — Instant Simulation & Seamless Microchannel Coil Workflow

- A Well-Fed World, Youth Climate Save and PAN International Launch PHRESH: A Global Directory of Plant-Based Hunger Relief Organizations

- Guests Can Save 25 Percent Off Last Minute Bookings at KeysCaribbean's Village at Hawks Cay Villas

- Trump's Executive Order Rescheduling Cannabis: Accelerating M&A in a Multibillion-Dollar Industry

Typical Standards: ASTM G155, ISO 4892-2, SAE J2527

Common Parameters: Irradiance 0.35–1.10 W/m² (at 340 nm), temperature Ambient ~ 100 ℃ ±2℃, humidity 50% ~ 98% RH

Ideal For: Automotive components, textiles, packaging, and outdoor construction materials

Technical Comparison: Choosing the Best Chamber for Your Material Durability Tests

| Feature | UV Weathering Chamber | Xenon Arc Chamber |

| Light Source | Fluorescent UV lamp | Xenon arc lamp |

| Spectrum Coverage | UV range (295–400 nm) | Full spectrum (280–800 nm) |

| Energy Cost | Low | High |

| Application Focus | Surface weathering | Full-spectrum light aging |

| Typical Test Duration | 300–1000 hours | 500–2000 hours |

If your product mainly suffers UV-induced surface damage, the UV chamber offers an efficient and economical option. However, for comprehensive sunlight simulation and color stability assessment, a xenon arc test chamber provides more realistic results.

More on Wisconsin Eagle

- Genuine Hospitality, LLC Selected to Operate Hilton Garden Inn Birmingham SE / Liberty Park

- Documentary "Prescription for Violence: Psychiatry's Deadly Side Effects" Premieres, Exposes Link Between Psychiatric Drugs and Acts of Mass Violence

- Price Improvement on Luxurious Lāna'i Townhome with Stunning Ocean Views

- Nextvisit Co-Founder Ryan Yannelli Identifies Six Critical Factors for Behavioral Health Providers Evaluating AI Scribes in 2026

- Moor Downs Golf Course Partners With Keeper Goals on New Protective Barrier Netting System

LIB Industry – Global Expertise in UV and Xenon Weathering Test Chambers

LIB Industry is a global manufacturer with over 16 years of expertise in environmental test chambers. We provide standard and customized solutions for UV, xenon, temperature & humidity, thermal shock, and IP dust and water ingress testing.

Supported by 5 service centers worldwide and lifetime technical assistance, LIB industry provides fast response, reliable quality, and complete testing solutions.

Website: www.libtest.com

Email: inquiry@libtestchamber.com

WhatsApp / Phone: +86 187 0087 5368

For expert guidance and tailored testing systems, contact LIB Industry — your trusted partner for environmental simulation and accelerated aging solutions.

Source: Xi'an LIB Environmental Simulation Industry

0 Comments

Latest on Wisconsin Eagle

- "BigPirate" Sets Sail: A New Narrative-Driven Social Casino Adventure

- Phinge CEO Ranked #1 Globally by Crunchbase for the Last Week, Will Be in Las Vegas Jan. 4-9, the Week of CES to Discuss Netverse & IPO Coming in 2026

- Tom Brady's Cloned Dog Sparks Ethical Debate: Biologist Ben Greulich Joins Marcus Hart

- TAP Announces Acting Classes for Young and Old

- Women's Everyday Safety Is Changing - The Blue Luna Shows How

- Microgaming Unveils Red Papaya: A New Studio Delivering Cutting-Edge, Feature-Rich Slots

- 5-Star Duncan Injury Group Expands Personal Injury Representation to Arizona

- The End of "Influencer" Gambling: Bonusetu Analyzes Finland's Strict New Casino Marketing Laws

- AI-Driven Cybersecurity Leader Gains Industry Recognition, Secures $6M Institutional Investment, Builds Momentum Toward $16M Annual Run-Rate Revenue

- TRIO Heating, Air & Plumbing Now Ranks #1 in San Jose

- Milwaukee Job Corps Center Hosts Alumni Day, Calls Alumni to Action on Open Enrollment Campaign

- When The Call Hits Home - Heartfelt Holiday Episode Focusing on First Responders and Family Wellness

- Golden Paper Identifies Global Growth in Packaging Papers and Upgrades Its High-End Production Capacity

- Champagne, Caviar Bumps & Pole Performances — Welcome the New Year Early with HandPicked Social Club

- A New Soul Album: Heart Of Kwanzaa, 7-Day Celebration

- Allegiant Management Group Named 2025 Market Leader in Orlando by PropertyManagement.com

- NAFMNP Awarded USDA Cooperative Agreement to Continue MarketLink Program Under FFAB

- Costa Oil - 10 Minute Oil Change Surpasses 70 Locations with Construction of San Antonio, TX Stores — Eyes Growth Via Acquisition or Being Acquired

- LaTerra and Respark Under Contract with AIMCO to Acquire a $455M, 7-Property Chicago Multifamily Portfolio

- Record Revenue, Tax Tailwinds, and AI-Driven Scale: Why Off The Hook YS Inc. Is Emerging as a Standout in the $57 Billion U.S. Marine Market