Trending...

- Controversial Vegan Turns Rapper Launches First Song, "Psychopathic Tendencies."

- From Cheer to Courtroom: The Hidden Legal Risks in Your Holiday Eggnog

- "Dr. Vincent Michael Malfitano Expands Monterey–Sicily Cultural Diplomacy With Major International Media Engagement"

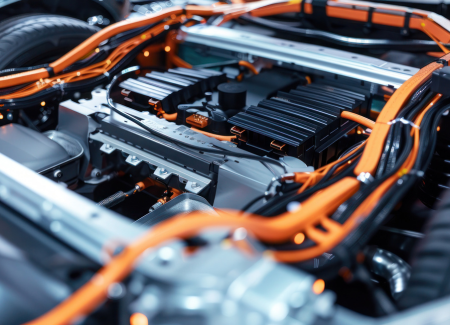

DALLAS, N.C. - WisconsinEagle -- Discover how one formulation enables cost-efficient, sustainable ESD packaging for the automotive industry without compromising performance.

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on Wisconsin Eagle

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on Wisconsin Eagle

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on Wisconsin Eagle

- Finland's Gambling Reform Promises "Single-Click" Block for All Licensed Sites

- Private Keys Are a Single Point of Failure: Security Advisor Gideon Cohen Warns MPC Technology Is Now the Only Defense for Institutional Custody

- Compliance Is the Ticket to Entry: Legal Advisor Gabriela Moraes Analyzes RWA Securitization Paths Under Brazil's New Legislation

- Coalition and CCHR Call on FDA to Review Electroshock Device and Consider a Ban

- Spark Announces 2025 Design Award Winners

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on Wisconsin Eagle

- NEW Luxury Single-Family Homes Coming Soon to Manalapan - Pre-Qualify Today for Priority Appointments

- Dominic Pace Returns to the NCIS Franchise With Guest Role on NCIS: Origins

- Anderson Periodontal Wellness Attends 5th Joint Congress for Ceramic Implantology

- UK Financial Ltd Completes Full Ecosystem Conversion With Three New ERC-3643 SEC-Ready Tokens As MCAT Deadline Closes Tonight

- AI Real Estate Company Quietly Building a National Powerhouse: reAlpha Tech Corp. (N A S D A Q: AIRE)

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Source: Premix

0 Comments

Latest on Wisconsin Eagle

- Controversial Vegan Turns Rapper Launches First Song, "Psychopathic Tendencies."

- Inside the Fight for Affordable Housing: Avery Headley Joins Terran Lamp for a Candid Bronx Leadership Conversation

- Canterbury Hotel Group Announces the Opening of the TownePlace Suites by Marriott Portland Airport

- Heritage at South Brunswick's Resort-Style Amenities for Any Age and Every Lifestyle

- T-TECH Partners with Japan USA Precision Tools for 2026 US Market Development of the New T-TECH 5-Axis QUICK MILL™

- Record Revenues, Debt-Free Momentum & Shareholder Dividend Ignite Investor Attention Ahead of 2026–2027 Growth Targets: IQSTEL (N A S D A Q: IQST)

- New YouTube Channel Pair Launches to Bring Entertainment Nostalgia Back to Life

- BRAG Hosts Holiday Benefit — Awards 10 Student Scholarships & Honors Timberland with the Corporate Impact Award

- FittingPros Launches Industry's First Data-Driven Golf Club Fitting Directory

- Take Control of Your Color Matching with Boston Industrial Solutions' Newly Expanded Natron® UVPX Series Ink Colors

- "Dr. Vincent Michael Malfitano Expands Monterey–Sicily Cultural Diplomacy With Major International Media Engagement"

- Kaufman Development Breaks Ground on Detroit Micro Data Center, Expanding Its National AI Platform

- Cummings Graduate Institute for Behavioral Health Studies Celebrates New DBH Graduates

- $80M+ Backlog as Florida Statewide Contract, Federal Wins, and Strategic Alliance Fuel Next Phase of AI-Driven Cybersecurity Growth: Cycurion $CYCU

- High-Conviction CNS Disruptor Aiming to Transform Suicidal Depression, Ketamine Therapeutics, and TMS - Reaching Millions by 2030

- Top10Christmas.co.uk Releases the UK Christmas Toy Trends 2025 Report

- Talagat Business Academy Announces Joint Certificate Program With The University of Chicago Booth School of Business

- LocaXion and Asseco CEIT Announce First-to-Market RTLS-Driven Digital Twin Platform for Healthcare, Manufacturing, and Logistics

- Slotozilla Launches New Report on How AI Is Reshaping Careers and Society

- When The Call Hits Home Explores EMDR Therapy for First Responders in Latest Podcast Episode